The EnBW offshore wind farm "Hohe See" is the third of four planned / realised wind farms of EnBW AG. "Hohe See" is located about 90 km north of the island of Borkum and about 95 km west of the island of Helgoland in the North Sea. The wind farm comprises 80 wind turbines of the 6.15 MW class. The main works wind turbines, foundations, internal park cabling and the transformer station are awarded according to international standard plant construction contracts (FIDIC Yellow Book). These include the planning, manufacture, delivery, assembly and commissioning of the respective trades.

New directions for new energy

The world of energy is becoming increasingly complex: growing energy demand is being met by ever more energy sources. These provide us with more and more challenges, ranging from generation via distribution to grid control. Factors such as technologies, the general public, markets, distribution, digitalisation and networks determine deadlines, processes and costs. Our focus is on wind energy, network growth and decommissioning, on and off shore, national and international.

-

Project Management

-

Project Control

-

Project Leadership

-

Contract & Claims Management

-

Risk Management

-

Strategy & Consulting

-

Building Information Modeling

-

Construction Management

-

Lean Management in Building Projects

-

Multi-Project Management / Portfolio Management

-

Recall Management

-

Supply Chain Management

-

Turnaround Management

Energy

We have in-depth sector knowledge – with our broad service portfolio we will support your individual project with a high level of technical skill and consultancy expertise as well as offer a variety of expert services to complement our standard project management services.

Selected references

provide exemplary insights into the diversity of projects as parts of a broad spectrum of experience. Further references on request under info@thost.de.

The construction of the wind farm with 80 Siemens SWT-3.6-120 wind turbines each with a nominal output of 3.6MW started in Spring 2014 to the west of the island of Sylt. Full commissioning was completed in 2016.

The wind farm was developed by Windreich. It comprises 80 wind turbines of the 5MW class. The plant became officially operational on 2nd September 2015.

The wind farm was built by RWE Innogy in the German Exclusive Economic Zone of the North Sea with 48 wind turbines.

The wind farm is located in the Dutch Exclusive Economic Zone in the south of the North Sea. It consists of two parts, each with 75 wind turbines. With a total output of 600MW, it was one of the biggest offshore wind farms in the world when it became operational in April 2017.

The wind farm is located in the German Exclusive Economic Zone in the North Sea, and should come into operational service in 2017. Northland Power is the majority owner with an 85% share.

The wind farm is a planned offshore wind farm from EnBW (Energie Baden-Wuerttemberg) with an installed capacity of 497MW. 71 wind turbines each with a nominal capacity of 7MW should be built.

An 800 and a 900 megawatt strong direct current connection was realised by TenneT in the project BorWin 2 & 3. In the future different wind farms situated more than 100 km from the coast can use this to feed large quantities of wind generated electricity into the grid.

An 800, a 916 and a 900 megawatt strong direct current connection was realised by TenneT in the projects DolWin1, 2 & 3. In the future different wind farms situated more than 100 km from the coast can use this to feed large quantities of wind generated electricity into the grid.

A 576 and a 690 megawatt strong direct current connection was realised by TenneT in the project HelWin1, 2 & 3 realisiert. In the future different wind farms situated more than 100 km from the coast can use this to feed large quantities of wind generated electricity into the grid.

A 240 km long 1,000MW HVDC between Southampton in England and the Normandy in France is being realised by RTE/National Grid in the project “Interconnexion France Angleterre 2”. The pipeline will contribute to grid stability between the British Isles and mainland Europe.

A 90km long 900MW HDVC between a converter station in Hilgenriedersiel, Germany and an offshore convertor platform 45km from the coast is being realised by TenneT Offshore GmbH in the project “DolWin6“. The offshore convertor platform DolWin converts AC into DC which is then transported to the mainland in a 45km long underwater cable. Tennet is constructing a convertor station and a substation nearby to convert the DC back into AC and to feed it into the grid.

The new pipeline Conneforde-Cloppenburg-Merzen brings electricity which the onshore wind turbines produce in the North to the South to the consumers. The project is making an important contribution in connecting the offshore wind farms.

The project SuedOstLink is being planned and implemented jointly by the transmission network operators 50Hertz and TenneT. SuedOstLink is currently in the planning phase.

NordLink is being realised as an HVDC between Germany and Norway with a route length of 623km. The convertor stations are being constructed in Wilster and Tonstad.

This onshore project is being realised with a new route and has the target of increasing the transmission capacity between Germany and Denmark. The construction of the west coast pipeline is necessary because the existing grid in Schleswig-Holstein has reached its limit.

Malženice power plant is a gas and steam combined cycle power plant in operation in Slovakia. Since the end of 2008, E.ON has built a power plant at the site of an old gas compressor station of the gas supplier SPP in 26 months. In combined operation, the power plant has an electrical output of approximately 430 MW gross and 417 MW net.

In Gönyü E.ON constructed a modern CCGT. The facility with a capacity of 400 MW has been on the grid since 2010. With an efficiency level of 58% Gönyü is one of the most efficient power plants in the world.

Reconstruction of 3 natural gas power stations in Egypt which, with a capacity of 4,800MW are the world’s biggest of their kind. At the locations of Beni Suef, Burullus and New Capital there are 12 gas turbines in operation in total and another 24 in the final stages.

Construction of a CCGT power station in Bucharest with a capacity of 185MW.

Planning, construction, delivery, turnkey erection, commissioning and trial operation of the multi-shaft CCGT plant at the site of the pre-existing Lingen power plant.

The coal-fired power plant in Wilhelmshaven has a net electrical output of 731 megawatts and can generate up to 5.5 billion kilowatt hours of electricity per year. This corresponds to about one percent of the total electricity produced in Germany.

Construction of Block 8 of the Rheinhafen steam power station in Karlsruhe with a capacity of 912MW and district heating of 220MW.

Hypercritical steam generators as pulverised coal fired boiler incl. Fuel supply system, furnace, flue gas denitrification facility, ash removal plant and ammonia supply.Construction of a brown coal power station as dual block facility of the most modern kind with two power station blocks (F and G), a total capacity of 2,200MW as replacement for 6 old lower capacity facilities.

Conversion Block 9 of Mannheim’s large scale power station. The power station produces district heating for approx. 120,000 households. Additionally, the DB Energie GmbH receives about 15% of its energy requirements for the German railway.

In 2015 in Eemhsaven near Groningen, a new modern power station became operational. It consists of the units A and B and has a 1,560 MW capacity.

Engineering services for the construction of a 1,100 MW coal-fired power plant.

The Stade nuclear power plant was operated in Stadersand from 1972 to 2003. It was the first nuclear power plant in Germany to be decommissioned after nuclear power was phased out and is currently being dismantled.

Würgassen nuclear power station in Beverungen was a 2nd generation boiling water reactor with a power station unit. It was operational from 1971 to the 26th August 1994. The nuclear power station was dismantled over 17 years at a cost of more than one billion euros.

The underground storage facility is a former salt mine in Lower Saxony which was commercially tested for and used for the end storage of nuclear waste between 1967 and 1978. In 2007 the final closure was requested and the recovery plan for the stored waste started.

The Konrad facility is an inoperative iron ore mine near Brunswick which is being converted into an end storage facility for radioactive waste with negligible heat generation.

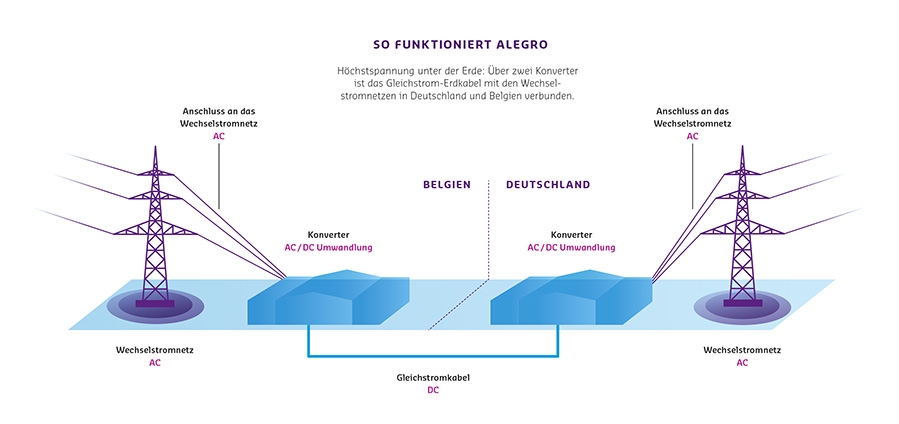

Project management for construction projects in the energy sector - ALEGrO

A total length of 90 km and a transport capacity of 1,000 MW - these are the key parameters of the Alegro (Aachen-Liége Electricity Grid Overlay) DC underground cable project. Construction of this first direct power link between Germany and Belgium began in autumn 2018 and it is scheduled to go into operation at the end of 2020. Construction projects of this kind are not only a technological planning challenge, but also offer many special features that need to be taken into account from the project management perspective

The demands on control, planning and organisation are particularly high in international energy construction projects. This is evident, for example, in the often complex approval procedures. For the successful implementation of a construction project - which normally begins with the compilation of all necessary documents - it is also necessary to manage and harmonize the interests of all stakeholders involved.

In order to master the numerous challenges in project management, project controllers are required to act as interface coordinators, especially in international construction projects. Only in this way can different interests be safeguarded and working methods and processes harmonized.

Cooperation is also crucial in risk management. Construction projects in the energy sector must be comprehensively analysed in advance for all possible risks. To do this, it is necessary to identify these together with all parties involved as early as the planning phase and to think and plan risk management from the outset throughout all construction phases. Subsequently, the risks can be uniformly defined, evaluated and tracked in a risk matrix. It is also important to plan countermeasures and to update or implement them in step with construction progress.

An additional requirement for construction projects in the energy sector are often the award procedures and especially their preparation and organisation. At Alegro, for example, EU tendering procedures and tenders for converters and cable production as well as for cable installation were coordinated. Not only was the right timing crucial here, but also the consideration of many different responsibilities.

Not infrequently, projects in the energy industry such as Alegro also attract a great deal of public attention. This is because many towns and municipalities, property owners and associations are often involved. In preparation for this, Amprion involved the public in the project at an early stage and implemented a carefully planned communication strategy, which makes a not inconsiderable contribution to the successful realisation of this project.

Picture sources:

Amprion GmbH | Daniel Schumann

Amprion GmbH | Marcus Pietrek

Source: Extract from EW magazine 2019 (Vol. 118), issue 3

EnBW Offshore Wind Farm "High Seas" - FIDIC Engineer

Services

- THOST has been assigned the role of engineer according to FIDIC Yellow Book for the trades "wind turbines" and "substation

- Project management services with assumption of essential client functions

- Conception & coordination of essential processes in the project

- Procedure Approval process by certifier and approval authority

- Process approval Basic & Detail Design

- Plan management concept

- Schedule management concept

- Commissioning / acceptance concept for inclusion in contracts

- Change and Contract & Claims Management

- Documentation of essential processes in a project manual

- Development of time scheduling and development of specifications for bidders / contractors

- Development of a document management system